-

Product CenterPRODUCT CENTER

-

Application IndustryIndustry INDUSTRY

-

Company ProfileCOMPANY INTRODUCTION

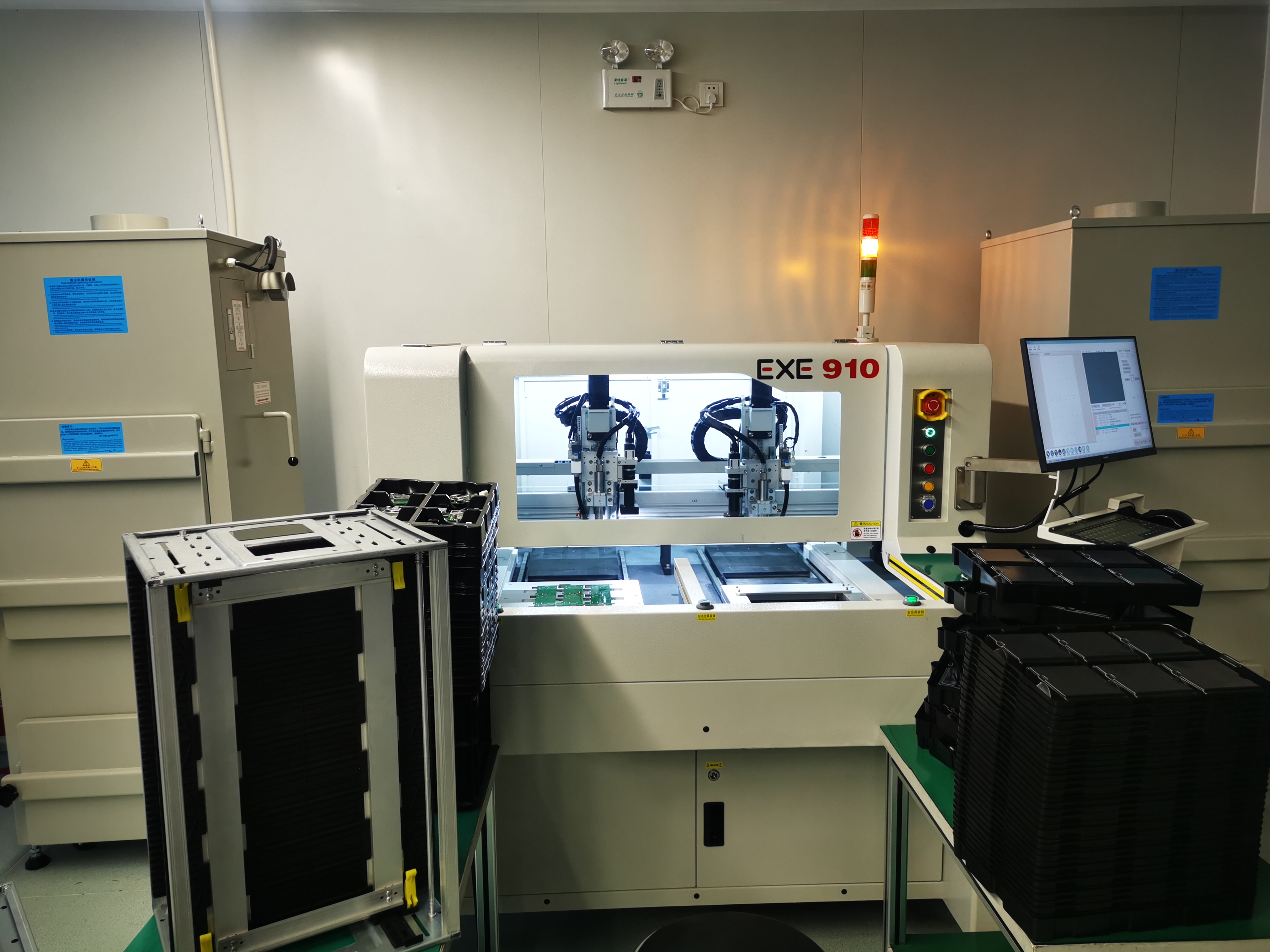

Automatic division machine is the use of milling cutter high-speed operation, in accordance with the pre-edited path of multi-connection PCB board equipment. Using human-machine interface, Windows XP operating system, simple and convenient, user-friendly interface design, automatic cutting path correction system, high pixel CCD program production, block program and single step program editing and modification, PCB loading and unloading device, interactive work between the two platforms, can effectively reduce the machine's waiting time, To achieve the desired production efficiency.

1. Reduce the internal stress generated when cutting the plate to less than 180ue to avoid tin cracks and damage to precision parts

2. Due to the depth of V-groove and tool loss, the distance between the upper round cutter and the lower straight cutter can be adjusted precisely

3. Electric hybrid design, double straight knife cutting, especially suitable for cutting precision SMD board and aluminum circuit board

4. The width of V-groove edge and parts shall not exceed 0.3mm, and the height shall be 60mm

5. Slitting speed is controlled by knob, slitting stroke can be set freely, LCD display. The device has three sets of electric eye protection

6. Minimize the internal stress generated when cutting the plate to avoid tin cracking

7. Broken end work is suitable for PCB of various thickness. The cutting plate stroke is less than 2mm, and the operation is safe

8. The tool can be turned over free of charge after wear

Points that should be paid attention to when feeding automatic plate dividing machine:

After the automatic dividing machine is energized and the stroke is determined, the corresponding indicator light must be ensured not to flicker; The whole process of electrostatic protection; PCB slot must be stuck to the blade, PCB must be placed horizontally; Do not put your hand into the machine when dividing the board; Press the switch until the blade stops running. In the process of cutting, PCB does not move and the round knife slides to ensure that the electronic components of the substrate are not damaged due to movement. The sliding speed of the round knife can be adjusted. According to the V-groove depth and tool loss, can accurately adjust the distance between the round cutter and the lower straight cutter, solve the problem of parts through the V-groove to achieve the plate, to minimize the internal stress generated when the plate cutting, to avoid tin cracks, cutting speed is controlled by the knob, cutting stroke can be set freely and displayed on the LCD.